Why Foam?

Ninety-seven percent of today’s fires are Class A in nature, often fueled by modern synthetic materials.

With flashover faster than ever, can you afford not to have:

|

|

Better Water

For years, fire departments have been utilizing chemicals to improve the effectiveness of water, thereby creating greater knockdown efficiency and increased firefighter safety. The additives in this water are sold in high concentration and require mixing to form a solution at percentages dictated by the application, or as recommended by the manufacturer. Hundreds of these concentrates are available today, but the majority fall into four basic categories: Class A Foam, Class B Foam, Emulsifiers and Gels.

For years, fire departments have been utilizing chemicals to improve the effectiveness of water, thereby creating greater knockdown efficiency and increased firefighter safety. The additives in this water are sold in high concentration and require mixing to form a solution at percentages dictated by the application, or as recommended by the manufacturer. Hundreds of these concentrates are available today, but the majority fall into four basic categories: Class A Foam, Class B Foam, Emulsifiers and Gels.

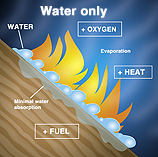

Water Only

By absorbing heat, water attacks one leg of the triangle. A natural characteristic of water called surface tension “holds” water together, resulting in larger droplets. This limits heat absorption for a given volume of water as a small percentage (outer 10% of droplet) actually removes heat, while the majority (inner 90% of droplet) runs off the fuel source and “out the front door.”

By absorbing heat, water attacks one leg of the triangle. A natural characteristic of water called surface tension “holds” water together, resulting in larger droplets. This limits heat absorption for a given volume of water as a small percentage (outer 10% of droplet) actually removes heat, while the majority (inner 90% of droplet) runs off the fuel source and “out the front door.”

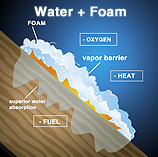

Water + Foam

Class A concentrate is simply a surfactant, similar to dishwashing soap, that reduces surface tension. When added to water, the resulting foam solution consists of many smaller droplets with much more surface area, allowing faster heat absorption. An example would be like cooling a glass of water with a single ice cube rather than crushed ice of the same volume. The crushed ice would cool it faster.

Class A concentrate is simply a surfactant, similar to dishwashing soap, that reduces surface tension. When added to water, the resulting foam solution consists of many smaller droplets with much more surface area, allowing faster heat absorption. An example would be like cooling a glass of water with a single ice cube rather than crushed ice of the same volume. The crushed ice would cool it faster.

In addition to creating smaller droplets, reducing the surface tension allows water to penetrate the fuel faster and deeper, dramatically raising the moisture content. This isolates the fuel leg of the triangle, increasing the resistance to burn. Finally, foam solution separates the fuel from oxygen with a vapor-securing barrier that provides excellent protection.

The proportion of Class A foam concentrate to water is dictated by use. A common rate for initial attack is 0.5%, overhaul 0.2% and exposure protection 1.0%. Application of the final solution can be achieved through a number of different mediums, including your standard nozzles, or specifically-designed aspirating nozzles.

Water + Foam + Air

Compressed Air Foam Systems (CAFS) is another technology making Class A foam even better. By injecting air into the solution, “bubblets” consisting of air surrounded by foam solution, are formed, which delivers a more efficient fire stream. The bubble structure is also much stronger and the additional energy from the air increases stream reach.

Compressed Air Foam Systems (CAFS) is another technology making Class A foam even better. By injecting air into the solution, “bubblets” consisting of air surrounded by foam solution, are formed, which delivers a more efficient fire stream. The bubble structure is also much stronger and the additional energy from the air increases stream reach.

Knockdown in 6 seconds!

The Viroqua, Wisconsin Fire Department responded to a fire in this 1890s two-story brick schoolhouse located 4 miles (6.45 kilometers) outside of town. With only 750 gallons (2839 liters) of water on-board and no hydrants nearby, this fire could have quickly become a real challenge. But this progressive department arrived on the scene equipped with a FoamPro 2001 foam proportioning system.

The Viroqua, Wisconsin Fire Department responded to a fire in this 1890s two-story brick schoolhouse located 4 miles (6.45 kilometers) outside of town. With only 750 gallons (2839 liters) of water on-board and no hydrants nearby, this fire could have quickly become a real challenge. But this progressive department arrived on the scene equipped with a FoamPro 2001 foam proportioning system.

Knockdown was accomplished in 6 seconds with 33 gallons (125 liters) of water and .17 gallons (.64 liters) of foam concentrate, using a 200 ft., 2-1/2” line with water flow of 328 gpm (1242 L/min) and 0.5% of Class A foam concentrate injected directly into the water stream.

Knockdown was accomplished in 6 seconds with 33 gallons (125 liters) of water and .17 gallons (.64 liters) of foam concentrate, using a 200 ft., 2-1/2” line with water flow of 328 gpm (1242 L/min) and 0.5% of Class A foam concentrate injected directly into the water stream.

Concentrates

- Class A Foam – Fire departments only recently are fully embracing the use of Class A foam. Designed for use on any Class A fire or three-dimensional fuel, Class A foam solution is a far superior firefighting agent than plain water . . . up to 3 to 4 times more effective!

- Class B Foam – Designed for use on Class B type fires or two-dimensional fuels, it forms a film over a contained fuel to extinguish and prevent re-ignition. Unlike Class A foam, manufacturers of Class B recommend the percentage of foam concentrate to water mixture based on the fuel to which it is applied. The most common proportioning rates are 1%, 3% and 6%. Some brands offer dual-usage concentrate, which may be applied on hydrocarbon and polar solvent fuels. Typically these will indicate two proportioning rates such as 1%x3%, 3%x3% or 3%x6%. Since high volumes of water and concentrate are typically utilized, cost, storage and logistical requirements are important to evaluate. The newer 1% versions may cost more per gallon of concentrate, but less per gallon of solution. They also require very accurate proportioning systems

- Other Concentrates – Emulsifiers are another type of additive used to provide long-term vapor suppression and aid in hydrocarbon recovery. Gels have proven to be excellent insulators and provide long-term exposure protection. Mixture rates for these can vary depending on application.

Better than water

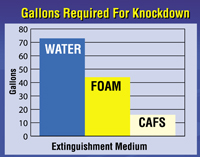

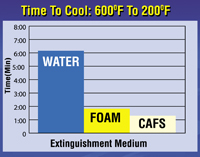

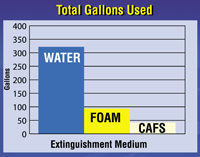

Comparison tests performed by Los Angeles County Fire Department on three identical 1100 sq./ft. homes demonstrate the powerful results of CAFS and Class A foam solution versus plain water.

The FoamPro Solution

Regardless of the additive, FoamPro offers the ultimate proportioning system for your new or retrofit apparatus. Our flow-based, microprocessor-controlled technology allows concentrate to be delivered on demand. By injecting into the discharge side, proportioning performance is not affected by external factors such as nozzle, length of hose lay, nozzle elevation or incoming pressure to the water pump. Full-fire pump discharge performance is delivered to the outlet as the flowmeter doesn’t restrict water flow. Best yet, no other system operates as easily and accurately as FoamPro. At the push of a button or flip of a switch, the system automatically reads water flow and injects concentrate to your desired setting from 0.1% to 10.0%. Unlike other proportioning technologies, FoamPro’s patented pump control means you are assured of unmatched accuracy across the full performance range, eliminating needless waste of concentrate and dollars.

Renowned for its reliability, FoamPro has proven itself since 1989 in the harshest conditions on fire grounds worldwide. We continually develop new and improved high-tech proportioning systems by incorporating ideas and suggestions from the field. To assure quality and compliance, only FoamPro requires system designs to be subjected to intense third-party testing. Stringent electronic emission control is verified according to MIL-STD 461E. Designs are then put to grueling SAE and U.S. military specifications by independent evaluators for heavy-use, off-road mobile apparatus.

Each system may also be checked for performance and accuracy without injecting concentrate into the water stream, saving dollars and addressing Class B environmental concerns.

FoamPro offers the broadest performance range in the industry, with models delivering from 0.01 GPM to 300 GPM of concentrate! Various models and associated options are designed to meet unique requirements as encountered in municipal, wildland, marine, industrial, ARFF, and CAFS applications.